Selecting the Right Cleaning Wiper: A Technical Overview

Choosing the correct wiper is critical for maintaining hygiene standards, optimizing cleaning performance, and ensuring compliance with facility protocols. Understanding material composition and functionality will help match the best wiper to each application.

Reducing Cross-Contamination: Best Practices

Using color-coded wiping systems is one of the most effective methods to prevent cross-contamination between distinct areas such as restrooms, foodservice zones, and office environments. By assigning specific colors to high-risk and low-risk areas, cleaning teams can limit microbial spread and maintain cleaner, healthier facilities.

Microfiber Wipers: Advanced Cleaning Technology

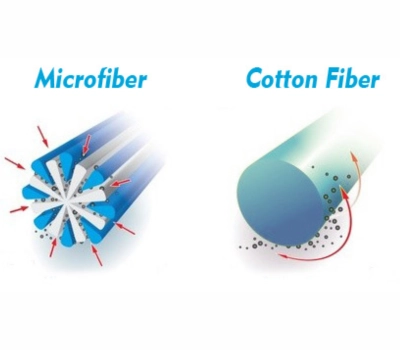

Composition & Structure: Microfiber wipers are crafted from ultra-fine synthetic fibers, typically a blend of 80% polyester and 20% polyamide (nylon). These fibers are split during manufacturing to create a star-shaped cross-section, increasing surface area and enhancing capillary action.

Performance Attributes:

- Electrostatic Attraction: The positive charge of microfiber attracts negatively charged particles like dust and microbes.

- High Absorbency: Capable of holding up to seven times their weight in water.

- Durability: Reusable variants can withstand hundreds of wash cycles without degradation

Ideal Applications:

- Healthcare settings for infection control.

- Cleanrooms and laboratories requiring lint-free cleaning.

- General janitorial tasks demanding superior soil removal.

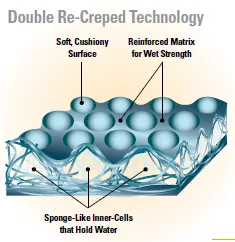

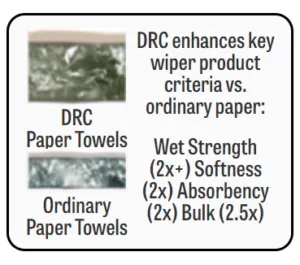

Double Re-Crepe (DRC) Wipers: Economical Absorbency

Composition & Structure: DRC wipers are made from cellulose fibers that undergo a double creping process, enhancing softness and bulk. A binder is added to improve wet strength.

Performance Attributes:

- High Absorbency: Excellent for soaking up water, oils, and solvents.

- Softness: Gentle on hands and surfaces, reducing the risk of scratches.

- Cost-Effective: Disposable nature makes them suitable for single-use applications.

Ideal Applications:

- Automotive workshops for grease and oil cleanup.

- Foodservice areas for quick spill management.

- General maintenance tasks requiring disposable wipers.

Hydroentangled Fiber (HEF) Wipers: Industrial-Grade Performance

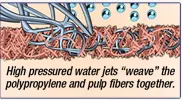

Composition & Structure: HEF wipers are produced by entangling cellulose and synthetic fibers using high-pressure water jets, eliminating the need for chemical binders. This process results in a strong, uniform, and low-lint material.

Performance Attributes:

- Strength: Maintains integrity when wet, suitable for heavy-duty tasks.

- Solvent Resistance: Compatible with various cleaning agents and solvents.

- Low Linting: Ideal for environments where contamination control is critical.

Ideal Applications:

- Manufacturing facilities for machinery maintenance.

- Aerospace and automotive industries requiring precision cleaning.

- Laboratories and cleanrooms where lint control is paramount.

Wiper Dispensing Solutions: Enhancing Efficiency

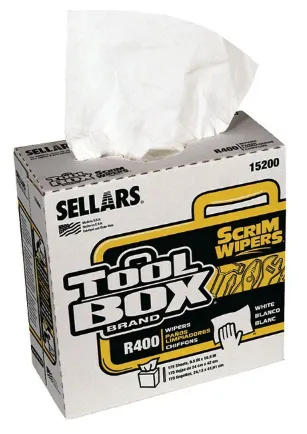

Pop-Up Boxes

Features:

- Single-sheet dispensing minimizes waste.

- Compact design suitable for tight spaces.

- Protects wipers from contaminants.

Buckets

Features:

- Portable and refillable, ideal for mobile cleaning tasks.

- Can be pre-moistened with cleaning solutions.

- Durable construction withstands industrial environments.

Jumbo Rolls

Features:

- High-capacity rolls reduce the frequency of replacements.

- Compatible with wall-mounted or floor-standing dispensers.

- Perforated sheets allow for easy tearing.

Choosing Based on Scientific Factors

Wiper Type

Microfiber

DRC

HEF

Best For

High-efficiency soil and microbial removal

High-volume wet wiping and general use

Critical cleaning, solvent tasks, machinery

Material Science Highlight

Split-fiber technology, electrostatic attraction

Creped cellulose for absorbency

Hydroentangled fiber matrix for strength and low lint

By understanding the composition and optimal applications of each wiper type, you can select the most effective solution for your specific cleaning needs.

The right cleaning wiper dramatically improves operational cleanliness, worker safety, and environmental hygiene outcomes.

What is Quat Binding?

“Quat binding” is a cleaning and disinfection term. It refers to the phenomenon where quaternary ammonium compounds (quats)—the active disinfectants in many sanitizers—get adsorbed or “bound” to certain surfaces or materials, which reduces their concentration in solution and therefore their effectiveness.

Here’s how it works:

Quats are positively charged disinfectant molecules.

Many types of cloths, sponges, and mops—especially cotton, cellulose, and some microfiber fabrics—carry a negative charge or have a porous structure.

When a quat-based disinfectant is applied with these materials, the quats can stick to (bind with) the fibers instead of staying in the liquid.

As a result, the disinfectant solution left on the surface (or in the bucket) has less active ingredient than the label requires, and it may no longer meet its stated kill claims.

This is why many manufacturers specify “quat-compatible” cloths, mops, or buckets (often made from synthetic blends) for applying their disinfectants, and why testing for proper ppm (parts per million) of quats after application is recommended.

Here’s a quick cheat-sheet of materials that don’t “grab” quats as badly and are usually labeled “quat-safe”:

| Material / Tool | Why It’s Safer |

|---|---|

| Microfiber specifically rated “quat-compatible” (some commercial microfiber brands) | These are specially finished so the positive quats don’t bind to the fibers. |

| Polyester or poly-blend cloths | Synthetic fibers have far less ionic attraction than cotton or rayon. |

| Non-woven disposable wipes (polypropylene or polyester) | Smooth, synthetic webs release quats instead of absorbing them. |

| Synthetic mop heads (rayon/polyester blends, looped end) | Designed for neutral charge and quick release of solution. |

| Plastic buckets / sprayers (HDPE, polypropylene) | Quats don’t bind to most plastics, so your dilution stays stable. |

Avoid cotton, cellulose sponges, untreated microfiber, and natural fiber mop heads if you want full disinfectant strength.

| Use (Quat-Safe) | Avoid (High Quat Binding) |

|---|---|

| Quat-compatible microfiber cloths (labeled “quat-safe”) | Standard untreated microfiber cloths |

| Polyester or poly-blend cloths | 100% cotton cloths or rags |

| Non-woven disposable wipes (polypropylene/polyester) | Cellulose or paper towels |

| Synthetic mop heads (rayon/polyester blends) | Cotton mop heads |

| Plastic buckets & sprayers (HDPE, polypropylene) | Metal pails or natural fiber wringers |

| Plastic spray bottles with synthetic triggers | Natural sponges or cellulose sponges |